Wastewater treatment

Wastewater treatment is a multi-stage water treatment, in which wastewater is cleaned before it is:

- Discharged to a body of water.

- Used for irrigation

- Recycled for other purposes.

Wastewater plants remove organic matter, nutrients, pathogens and industrial waste.

Wastewater treatment usually consists of four sequential processes:

- Preliminary treatment – removal of floating materials, grit and oily substances.

- Primary treatment – removal of suspended organic solids.

- Secondary treatment – removal of dissolved and colloidal organic matter.

- Tertiary treatment – additional purification to achieve certain water quality criteria.

The unit operations commonly used in wastewater treatment include physical, chemical and biological treatments.

Common physical treatments – screening, comminution, flow equalization, sedimentation, flotation, flocculation, media filtration etc.

Chemical processes – chemical precipitation, coagulation, adsorption, chlorination etc.

Biological processes – activated sludge, aerated lagoons, trickling filters, pond stabilization, anaerobic digestion, biological nutrient removal etc.

PRELIMINARY TREATMENT

Wastewater contains large solids and grit that might interfere with the treatment process, clog or wear the water treatment equipment.

The preliminary treatment unit operations are designed to remove large suspended or floating solids. This treatment begins with passing the wastewater through bar screens, grinders and then through grit separators.

Grit refers to the relatively heavy inorganic solids, that settle faster than organic material. Grit includes: sand, silt and gravel, cinders, egg shells, bone chips, shredded garbage and other heavy substances that are small enough to pass through the bar screens.

Grit removal is essentially a sedimentation process. Since organic suspended material and grit have different properties and different way of disposal, organic suspended solids are removed in a separate process.

Floating matter, such as oil, fat, grease, soap etc. is also removed in the preliminary treatment, passing the water through skimming tanks.

It is important to remove these floating materials, as otherwise they might interfere with the activated sludge process or create scum.

PRIMARY TREATMENT

Previous steps were aimed to protect the equipment, avoid clogging and to make the water easier to treat.

The primary treatment is a sedimentation process, aimed to remove suspended organic solids that were not removed in the preliminary treatment.

In the preliminary treatment, most of the suspended organic materials remain in the wastewater.

For sedimentation to occur, flow is slowed down considerably in a sedimentation tank, usually referred to as primary sedimentation tank or primary clarifier.

In the sedimentation tank, heavier organic solids are removed by gravitation.

Primary sedimentation can achieve 50-70% removal of suspended solids and 30-40% of BOD.

Sedimentation can be applied with or without the aid of coagulants.

|

Parameter |

Removal efficiency with coagulants (%) |

Removal efficiency |

|

TSS |

60-90 |

40-70 |

|

BOD5 |

40-70 |

25-40 |

|

COD |

30-60 |

20-30 |

|

Bacteria |

80-90 |

50-60 |

SECONDARY TREATMENT – BIOLOGICAL TREATMENT

The primary treatment cannot remove all dissolved and fine colloidal organic matter.

A biological treatment is required for removing those remaining components.

The treatment uses microorganisms – bacteria, algae, fungi, protozoa, nematodes – that decompose the organic material to inorganic forms, i.e. remove BOD.

All biological processes are based on microorganisms that feed on the organic contaminants in the water and remove BOD.

The biological treatments can be classified as:

Aerobic processes

Anaerobic processes

Pond processes

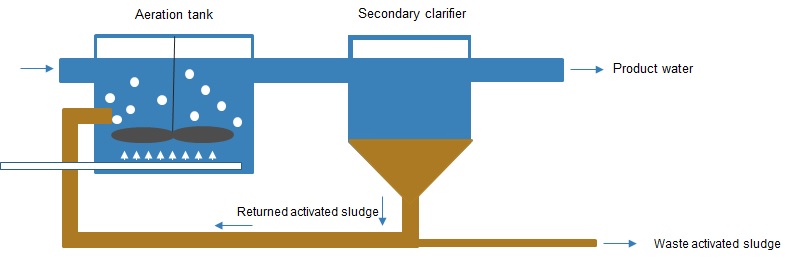

The most common process is the activated sludge process, which is an aerobic process.

In the activated sludge process, bacteria is continuously mixed with wastewater and digest organic contaminants.

Air is injected to the water in order to provide the oxygen demand of the microorganisms and to keep the solids in suspension and in contact with the bacteria.

As the bacteria grow, they clump together and create larger particles that settle to the bottom of the tank. This is the ‘activated sludge’.

Some of this sludge is returned into the wastewater to help maintain required level of bacteria in the tank.

There are different configurations of the process and flows, including plug flow, batch reactors and complete mix reactors.

TERTIARY TREATMENT

The tertiary treatment includes additional unit operations in order to bring the wastewater to the quality defined by the intended use of the water. Such processes may include coagulation-flocculation, filtration, disinfection, softening, activated carbon filtration, membrane filtration, such as reverse osmosis, and more.