Membrane bioreactors

Membrane bioreactors (MBRs) are becoming increasingly popular as they provide an alternative to conventional activated sludge treatment processes that use secondary clarifiers and trickling filters. They combine membrane filtration technology with biological treatment, which allows us to produce high quality effluent with less space requirement as compared with other conventional treatment plant configurations.

Membrane bioreactors (MBR) are a form of wastewater treatment that combines membrane filtration with biological treatment.

MBRs are a form of wastewater treatment that combines membrane filtration with biological treatment. The process generally begins with a primary clarification stage, which removes suspended solids from the water. Next, secondary biological treatment uses microorganisms to break down organic matter in the water. Then, the effluent stream is purified through membrane filtration

MBR systems can be used to treat many types of wastewater streams including industrial waste, domestic sewage and municipal effluent — even storm water runoff from polluted urban areas.

The MBR process

Membrane bioreactors are comprised of two important parts: the membrane, and the biological processes that take place in the reactor. While membranes often come in different forms and compositions, they all have one thing in common: they allow only specific materials through them while blocking out impurities or contaminants.

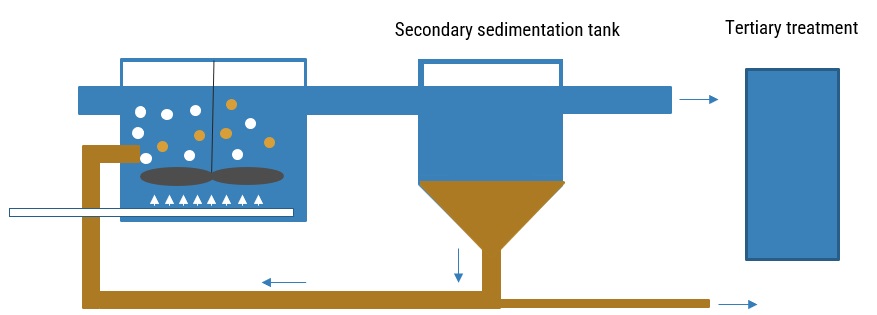

In a MBR system, water is passed through the aeration tank and then through membranes. The membranes replace the sedimentation tank in the conventional treatment. They can be either immersed (iMBR) in the aeration tank or side-stream (sMBR). Air bubbles are injected and create turbulence which helps avoiding membrane fouling.

The MBR system allows for high quality effluent, as the membranes filtrate also bacteria, viruses and nutrients, in addition to suspended matter. As a result, there is no need for secondary sedimentation, filtration, and disinfection. This allows for smaller treatment facilities or reduced costs of operation when compared with traditional technologies.

The energy costs for operating an MBR are higher than in the conventional treatment. However, effluent quality is better and less chemicals are used during treatment due to increased efficiency at separating microorganisms from water — reducing pollutants released into municipal sewers, which often lead back into waterways where they can cause further damage to ecosystems downstream.

The The MBR process uses microfiltration or ultrafiltration membranes in place of secondary clarifiers, which were traditionally used to separate out biological floc.

The MBR process is an alternative technology to the traditional activated sludge process. In MBR, microfiltration or ultrafiltration membranes are used instead of secondary clarifiers.

The secondary clarifier is traditionally used to separate out biological floc from wastewater by passing it through a series of sedimentation tanks that allow suspended solids to settle and be removed. Microfiltration and ultrafiltration membranes are more efficient at separating out biological floc.

Conventional activated sludge treatment

The combination of membrane technology with the activated sludge process makes it possible to produce a very high-quality effluent with less space requirement as compared with other conventional treatment plant configurations.

Membrane Bioreactors are designed to remove large quantities of suspended solids, suppress odors, and treat wastewater. The micro-porous membranes remove pollutants from wastewater much like a coffee filter or cloth towel to trap contaminants as they pass through the membrane. The membranes have a tiny pore structure that allows water molecules to pass through unimpeded while filtering out larger particles such as suspended solids and bacteria.

Ultrafiltration (UF) membranes have even smaller pore sizes than Microfiltration (MF) and can be used for high purity applications where the removal of dissolved organics is critical in maintaining product quality or purity levels required by pharmaceutical companies or food producers. The smallest pores on UF membranes will only permit molecular-sized substances such as salts and sugars through while leaving behind larger organic compounds.