Activated sludge – primary Control parameters

Three major control parameters are used in the activated sludge process: F:M ratio (Food:Microorganisms ratio), CRT (Cell Residence Time) and RAS flow rate (Return Activated Sludge flow rate).

Adjusting these three parameters controls the entire process. The explanation of each of them is given herewith.

FOOD:MICROORGANISMS RATIO

The F:M ratio is one of the key parameters of the activated sludge process. The organic load (food for the bacteria) must be balanced with the amount of microorganisms in the tank, in order to maintain the equilibrium in the system.

Both F and M have units of mass.

F = Influent BOD X Flow rate

M = MLVSS x Vaeration tank

Since the plant operator cannot control the influent BOD, the F:M ratio is used to determine the desired MLVSS level.

Example:

Aeration tank volume: 500 m3

Influent BOD: 350 ppm

Influent flow rate: 300 m3/day

Desired F:M value: 0.3

What is the MLVSS (mg/L) that has to be maintained?

Solution:

F= BOD x Flow rate = 350 ppm x 300 m3/day = 350 x 300 / 1000 = 105 kg/day.

F:M = 0.3

M= 105/0.3 = 350 kg.

MLVSS= M/Vaeration tank = 350 kg / 500 m3= 0.7 kg/m3 = 700 mg/L.

Common desired F:M ratios in various activated sludge process:

Extended aeration: 0.05 < F/M < 0.15

Conventional activated sludge system: 0.2 < F/M < 0.4

Completely mixed: 0.2 < F/M < 0.6

High rate: 0.4 < F/M < 1.5

The Essentials of Water Treatment

Learn the fundamentals of water treatment and latest technological advances to be a professional in the industry. This book takes you through the theory and practice of water treatment processes, explaining the different unit operations, their design parameters and operating considerations. All explained in an easy to read manner so you can have a clear understanding of each technology.

CELL RESIDENCE TIME (CRT)

The Cell Residence Time is the number of days bacteria or mass of bacteria remain in the secondary treatment train. CRT is controlled by the amount of sludge wasted.

CRT = MLVSS (in kg in the aeration tank) / WAS VSS.

Where WAS VSS stands for WAS Volatile Suspended Solids. It Is the concentration of suspended solids in the waste activated sludge, expressed in kg/day.

For example:

MLVSS = 3,500 mg/L

Volume of the aeration tank = 2,000 m3

WAS VSS = 6,000 mg/L

The sludge is wasted at a flow rate of 250 m3 a day

What is the CRT?

Solution:

MLVSS in kg = 3,000 (mg/L) X 2000 (m3) / 1,000 = 7,000 kg

WAS VSS in kg = 6,000 (mg/L) X 250 (m3/day) / 1,000 = 1,500 kg/day

CRT = 7,000/1,500 = 4.7 days.

Additional equations and parameters are being used by different engineers and plant operators to get an indication of the age of the sludge. For example, SRT (Solids Retention Time) and MCRT (Mean Cell Residence Time).

The “right” CRT is determined by monitoring the effluent quality and may also vary seasonally.

CRT is a control parameter. Controlling the CRT is done by adjusting the flow rate of the wasted sludge.

For example:

Desired CRT is 4 days.

MLVSS in kg = 2,000 kg

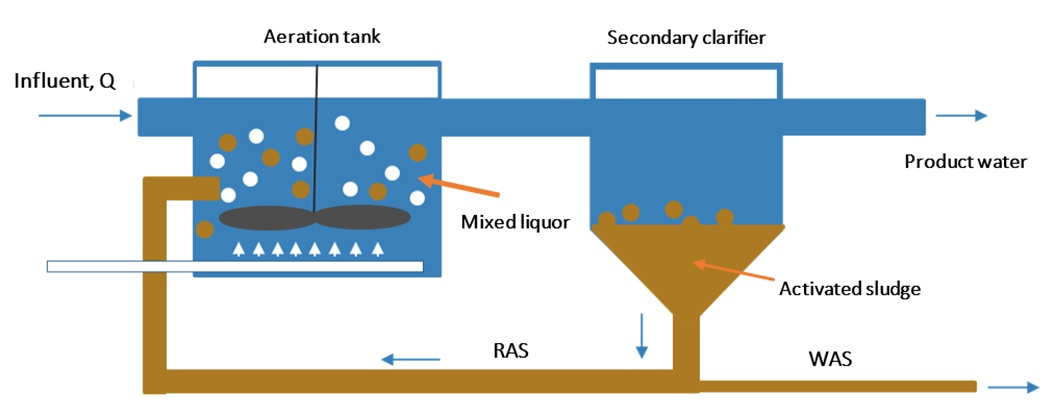

RAS VSS = 7,000 mg/L = 7,000 g/m3 (Note that the concentration in mg/L of RAS VSS = WAS VSS… See the image above).

What is Qw, the required flow rate of the wasted sludge?

WAS VSS (kg) = MLVSS (in kg) / CRT = 2,000 / 4 = 500 kg/day

Qw = 500 (kg/day) x 1,000 (g/kg) / 7,000 (g/m3) = 71.4 m3/day

RETURN ACTIVATED SLUDGE RATE

This is the flow rate in which a portion of the settled activated sludged is returned to the aeration tank in order to maintain the microorganisms level.

RAS flow rate = Q x [MLSS / (RAS SS – MLSS)]

Where

Q – the flow rate of the influent (wastewater entering the plant)

RAS SS – suspended solids concentration in the return activated sludge

For example:

Q = 5,000 m3/day

MLSS = 650 mg/L

RAS SS = 7,000 mg/L

RAS flow rate = 5,000 x [650 / (7,000 – 650)] = 511 m3/day