The Activated Sludge Process

The primary treatment cannot remove all dissolved and fine colloidal organic matter.

Therefore, a biological treatment is required for removing those remaining components. All biological processes are based on microorganisms that feed on the organic contaminants in the water.

The biological treatment uses microorganisms such as bacteria, algae, fungi, protozoa and nematodes that decompose the organic material to inorganic forms, i.e. remove the BOD (Biochemical Oxygen Demand).

The biological treatments can be classified as aerobic processes, anaerobic processes and pond processes. These can be further classified as suspended growth systems and attached growth systems.

One of the most common biological treatments of wastewater is the activated sludge process.

DESCRIPTION OF THE ACTIVATED SLUDGE PROCESS

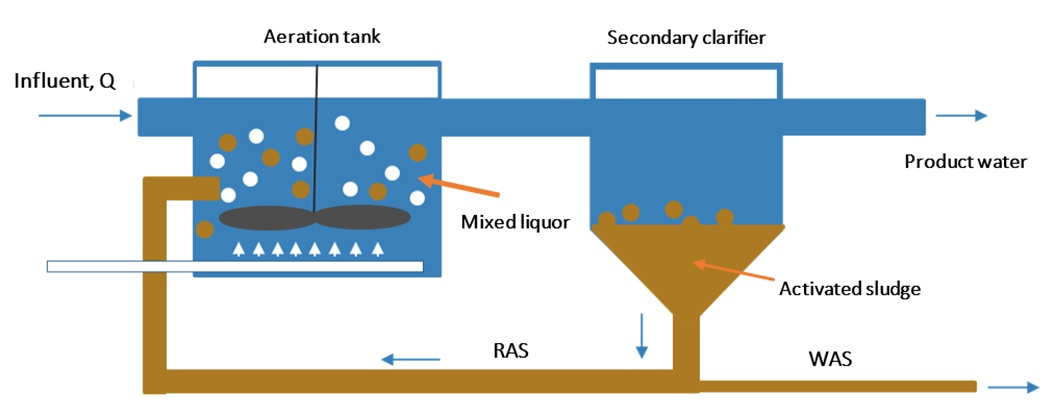

In the activated sludge treatment, bacteria is continuously mixed with the wastewater and digest the organic contaminants.

Air is injected to the water in order to provide the oxygen demand of the microorganisms and to keep the solids in suspension and in contact with the bacteria.

As the bacteria grow, they clump together and create larger particles that settle to the bottom of the tank. This is referred to as ‘activated sludge’.

Some of this sludge is returned into the water to help maintain required level of bacteria in the tank.

The process can be designed in different configurations. Each configuration has its own advantages and disadvantages. Therefore, when designing the reactor, one should design the configuration that most suitable to the specific process conditions.

The most common configurations are:

- Simple/conventional configuration

- Batch reactors

- Complete mix

- Extended aeration

FACTORS AFFECTING THE EFFICIENCY OF THE PROCESS

Many factors affect the efficiency of the activated sludge process. Such factors include:

- The type of reactor (configuration).

- The aeration

- The Food to Microorganisms ratio – F/M ratio

- pH and temperature of the water

- Nutrients in the water

- The detention time

Calculations that related to the process vary according to the configuration of the reactor and the specific conditions of the process. Nevertheless, the terms and parameters used to design the process and control it remain the same.

COMMON TERMS AND PARAMETERS

Mixed liquor – the mixture of activated sludge and the wastewater.

MLSS – Mixed Liquor Suspended Solids. The total concentration of suspended solids in the mixed liquor. Measured in units of mg/L or g/L.

Consists mainly of non-biodegradable suspended solids and microorganisms.

MLVSS – Mixed Liquor Volatile Suspended Solids. The volatile solids consist of mostly microorganisms and organic matter. Approximately equals to the concentration of microorganisms in the aeration tank.

HRT – Hydraulic Residence Time. This is the time the influent spends inside the reactor.

HRT = Vreactor/ Qinfluent

RAS – Returned Activated Sludge. Refers to the volume of sludge that is returned to the reactor.

WAS – Waste Activated Sludge. This is the volume of sludge that is removed from the system. The excess sludge has to be wasted, in order to maintain a desired level of MLSS in the system.

CRT – Cell Residence Time. The number of days the bacteria or mass of bacteria remain in the secondary treatment train. CRT is controlled by the amount of sludge wasted.

CRT = MLVSS (in kg in the aeration tank) / WAS VSS (in kg/day).